The factory

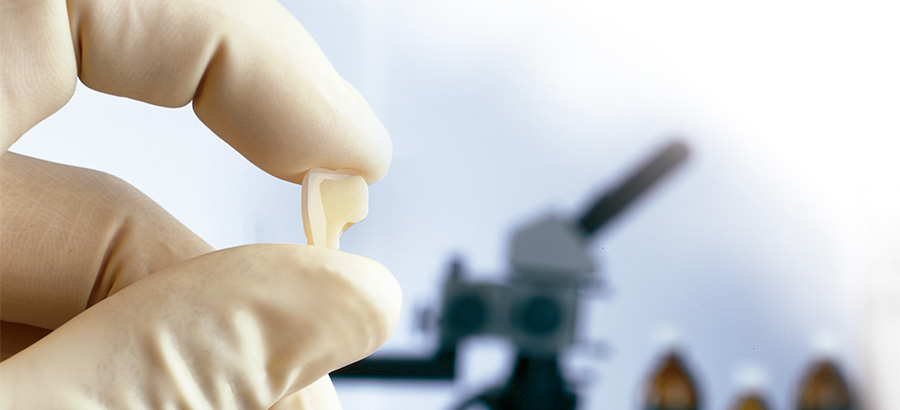

Homogeneity, piece by piecePreparation of resins

Following strict quality protocols, we create and pigment resins which are later used as the raw material for making the layers. These layers are then combined into other layers, giving each one of the artificial teeth the colour specified in the shade guide.

The natural appearance and the permanence of the colouring have made Unidesa-Odi famous throughout the world.

Automated polymerization of the layers

Once the moulds have been prepared and placed in the trays, they are introduced into an automatic production chain patented by Unión Dental under the name SICM. This moulding process allows Unidesa-Odi to inject the corresponding resins into each one of the layers at a specific time so that they are polymerized under the right pressure and temperature conditions.

The hardness and resistance to abrasion of Unidesa-Odi products are forged here.

Mineral pigments provide our products with their colours, which remain unaltered by the passage of time.

Strict protocols guarantee that the combination of different resins in each layer gives each tooth the necessary colour

Classification and packaging

The polymerized teeth are then taken to the room where they are classified and assembled on the cards.

The classification process is conducted using an artificial vision system and is carried out not only as a means of classifying the teeth, but also to discard any which for whatever reason might not comply with the quality standards we have set ourselves.

Lastly, before preparing the orders, the artificial teeth are mounted on cards and are checked one more time in order to ensure that the customer receives a product that everyone can trust.